About Us

For the next great business

With more than 25 years of industrial experience and working with companies of highest standards we bring in automation for the textile industry in a way suitable for the ground level people to operate, utilise and maintain them without the need for high skill set. We understand the requirements of each customer and customise the system just to suit their process and to make use of it to the maximum extent. Building the system to suit to your needs is our passion. All our systems are built with high quality components and materials to ensure reliability and durability. Machines and systems developed by us for other manufacturers are performing in the industry over several years. Our systems are equipped with remote servicing facility and all diagnosis can be done online with the help of mill technicians.

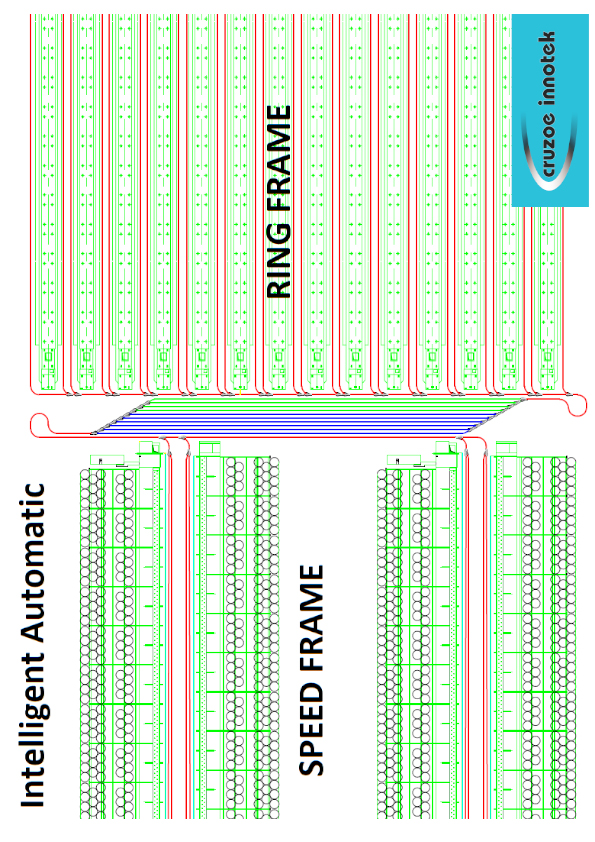

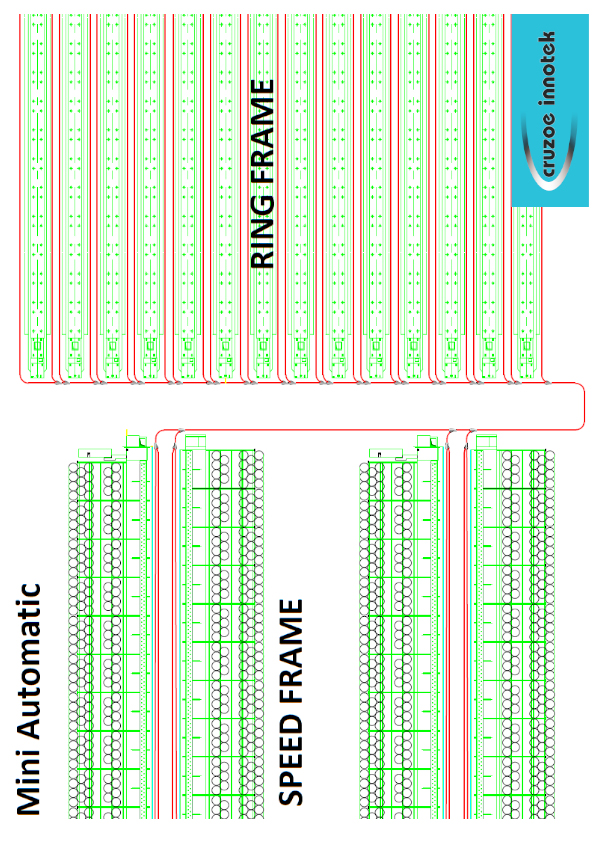

Intelligent Bobbin Transport System

Bobbin Stripper

Our Services

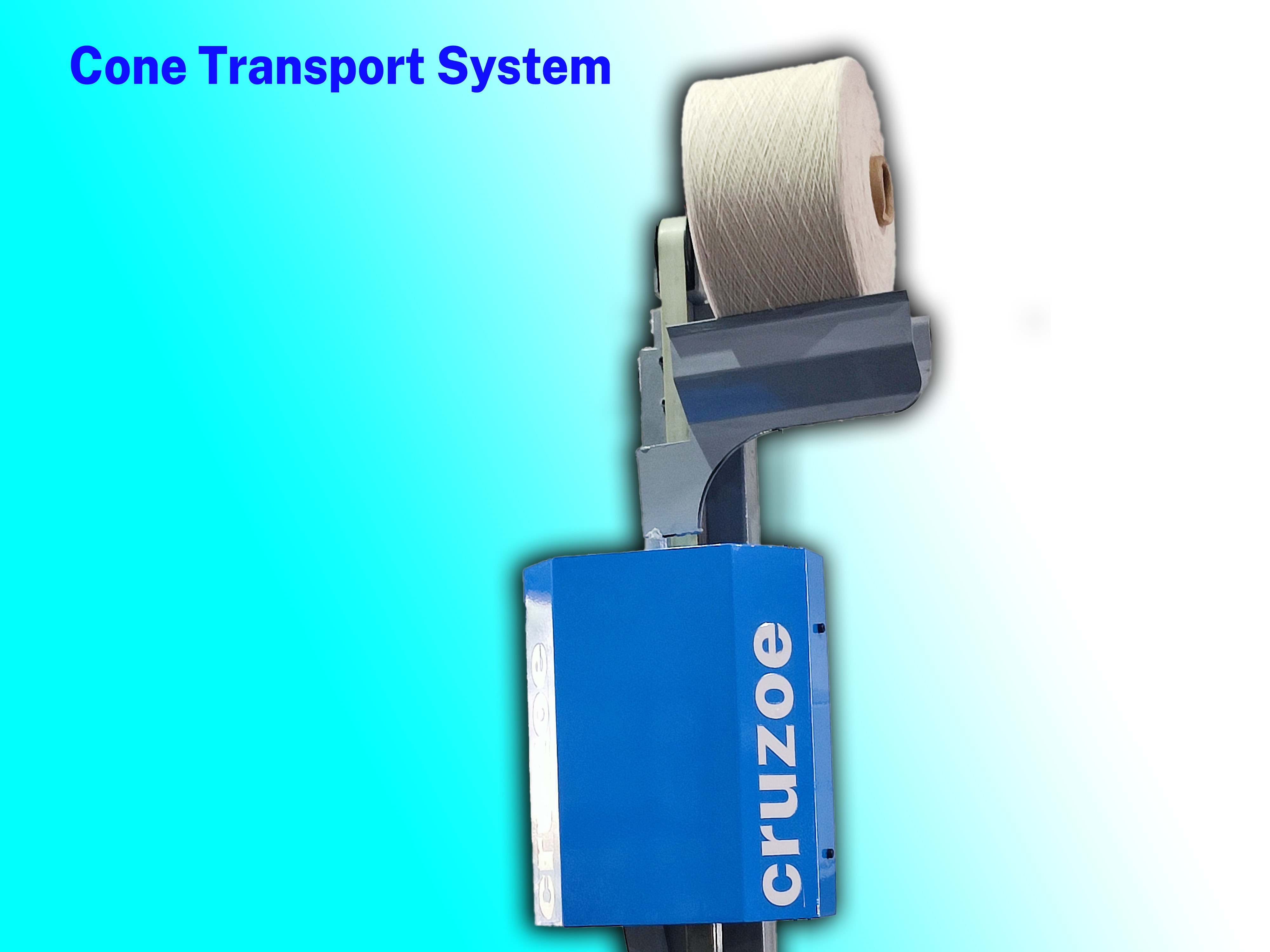

Cone Transport System

This system reduces the manual labour required to push the trolleys. The count mix-up is completely avoided. The system provides soft handling of the cones which avoids any damage to the outer layer.

Bobbin Transport System

This system uses overhead transport and hence the ground floor is free from movement of trolleys and additional manpower to push the trolleys. It helps to improve quality of the yarn produced by reducing damages of the outer layer of the bobbins due to manual handling and trolley loading. .

Automation Consultancy

We are here to take care of all your automation processes. Automation increases the efficiency, quality and throughput of your production. The processes involved in segregation and transportation can be automated.

Software Development

We are focused also in developing simple innovative software solutions and ideas to industries which help them systemize their process.

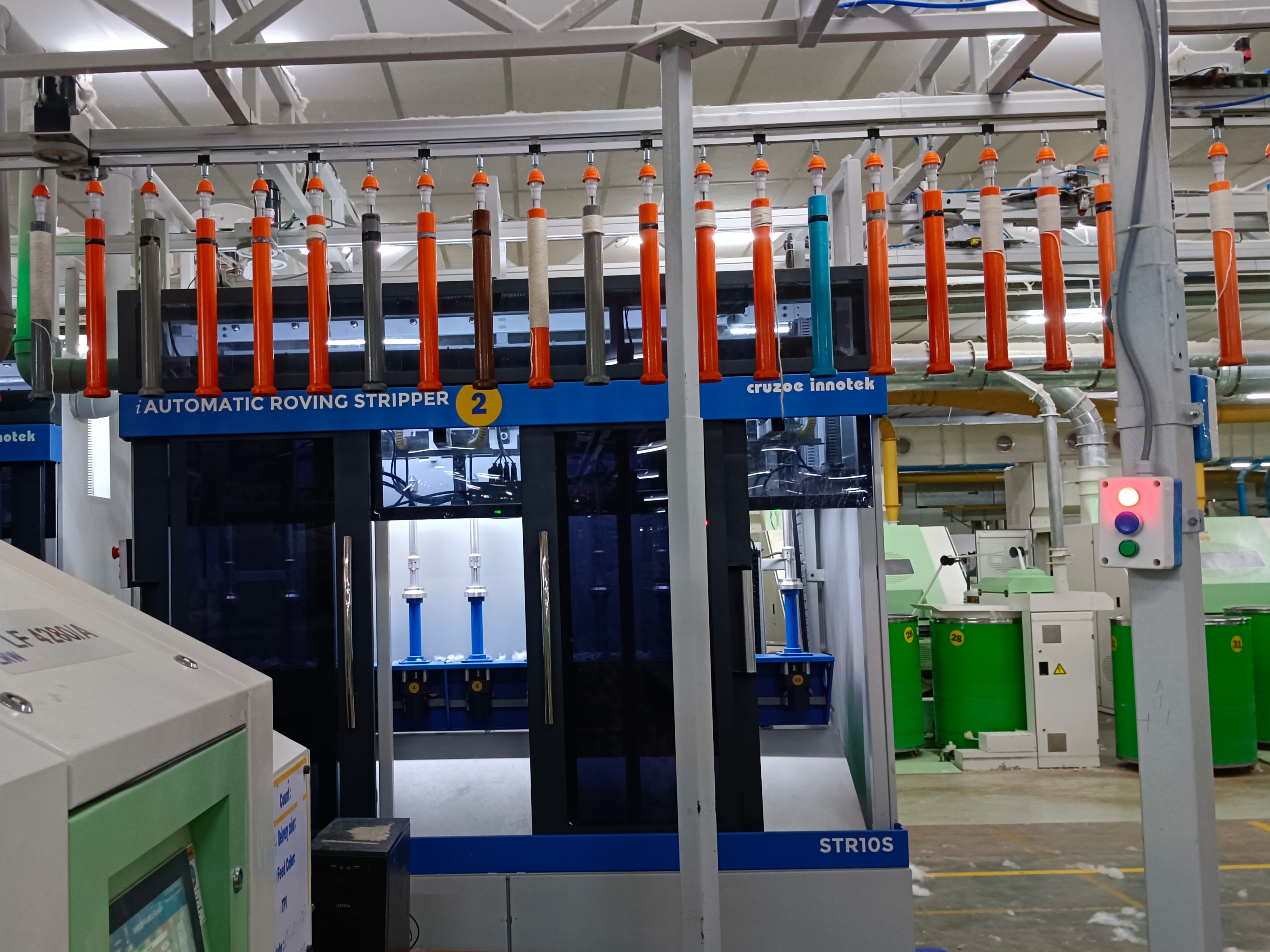

Roving Bobbin Stripper

An innovative product for making the bobbin ready for production. This product removes the unwanted residue roving from the bobbin automatically.

Roving bobbin Exchanger

A product which comes alsong witht eh automatic BTS for automatically exchange the empty bobbin with the new one in the train.

Portfolio

Contact Us

Office Address

CRUZOE INNOTEK PRIVATE LIMITED,SF No. 518/2, 15(4) Indira Nagar,

Chithannapuram Podanur, Coimbatore South,

COIMBATORE - 641 023 TAMILNADU-INDIA

GSTN: 33AALCC5628E1ZS

Factory Address

CRUZOE INNOTEK PRIVATE LIMITED,E-35, E Shed, Pollachi Main Road,

Kurichi Industrial Estate,

COIMBATORE - 641 021 TAMILNADU-INDIA

GSTN: 33AALCC5628E1ZS